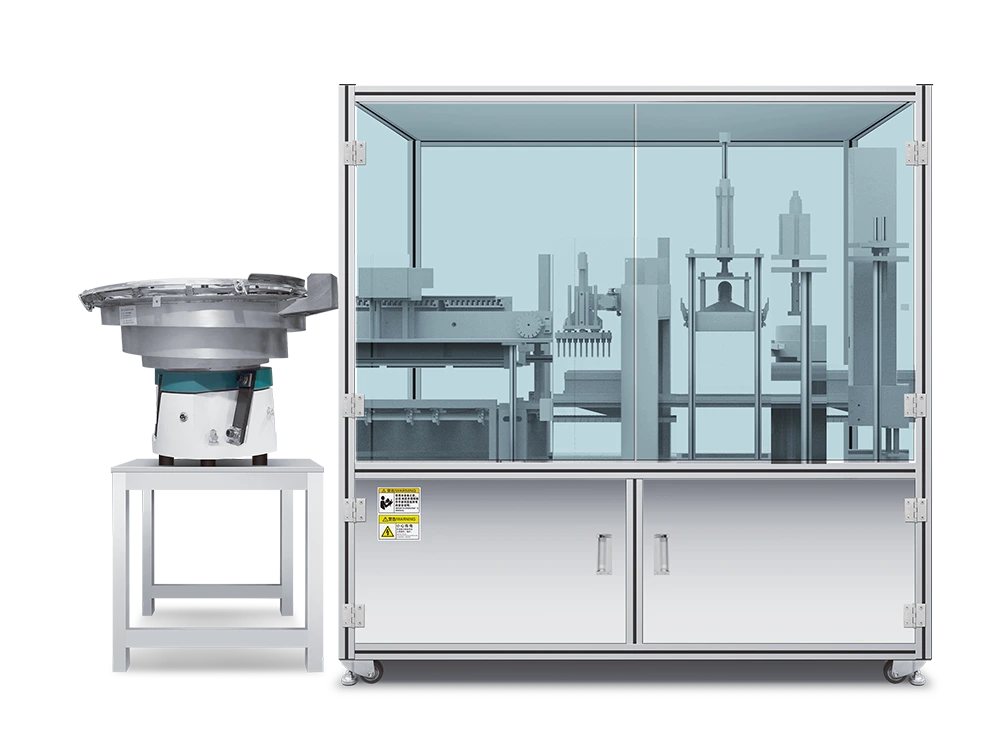

Mini/Capillary Blood Collection Tube Assembly Production Machine

Mini Blood Collection Tube Assembly Production Machine is used for micro blood collection tube assembly. It includes: tube loading, reagent/chemical spraying/filling (EDTA, clot activator, sodium citrate, lithium heparin, sodium heparin), chemical drying, cap adding, foam tray loading.

Mini/Capillary Blood Collection Tube Assembly Production Machine

|

Main Technical Parameters |

|

|

Production capacity |

10,000-12,000 pcs/h |

|

Tube size |

Ø11*45m (available for PET, Glass), can be customized |

|

Cap size |

As per client samples |

|

Control way |

Touch screen operation, PLC Control |

|

Dosing system |

10 sets of precision syringe pump for DNA liquid solution: 100-900ul±6% |

|

Detecting system |

Reverse tube detection before additive dosing-spraying Alarm function in case of lack of foam tray storage. |

|

Vacuum degree |

0 ~ -95Kpa ±6% for vacuum tubes Numerical control for vacuum pressure, Frequency conversion control for vacuum pump |

|

Configurations |

1) Tube loading (with vibration bowl tube feeding) 2) EDTA/Heparin precision dosing (10 nozzles) 3) BCA (clot activator) precision dosing (10 nozzles) 4) Sodium citrate filling (5 nozzles) 5) Chemical drying (3 sets) 6) Cap capping (with vibration bowl cap feeding) 7) Foam tray loading |

|

Air consumption |

Max. 1m3/min; Air supply pressure P: 0.7Mpa≤P≤1Mpa |

|

Power |

20KW/AC380V |

Work Flow

Tube loading -- Reverse tube detection -- Chemical filling (EDTA, clot activator, sodium citrate, lithium heparin, sodium heparin) -- Chemical drying -- Cap adding -- Foam tray loading -- Sealing and shrink packing -- Finished product.

more than 20 years experience in manufacturing vacuum blood collection tube automatic production lines.

fAQ

Leave a message