Blood Collection Tube Machine Automatic Production Line Overall Solution Provider.

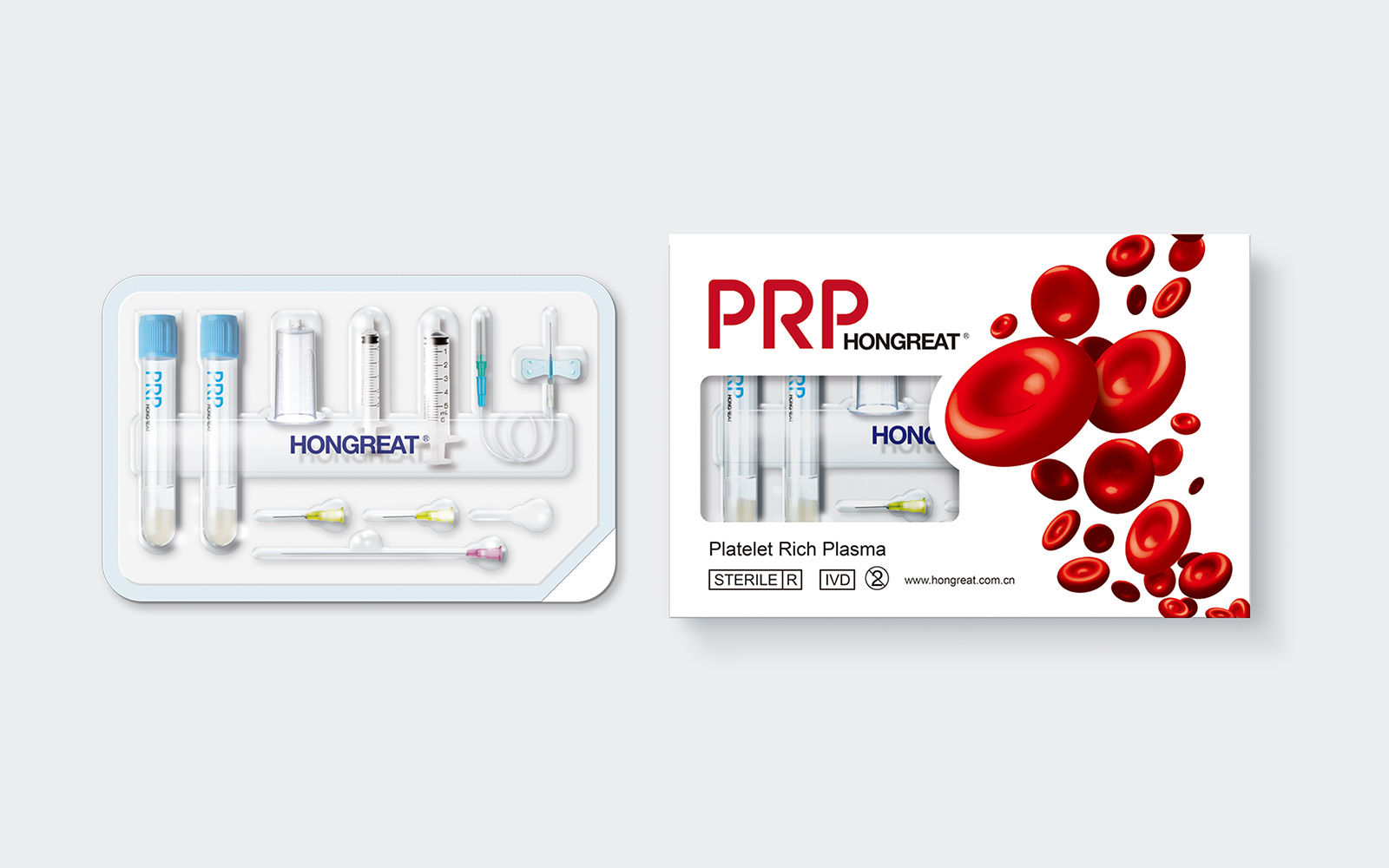

PRP Tube Production Overall Solution

HONGREAT® overall solution for PRP blood tube covering all aspect of services, include pre-production technology suggestions, workshop design, production technology, packaging technology, production equipment and raw materials. With over 20 years of experience & 18 unique patented technologies for blood tube production line, HONGREAT can support you to produce reliable, stable and high quality PRP tube.

It's with accurate filling to ensure the product quality & reduce gel waste to save enterprise cost. Specially designed for blood collection tube, stable, reliable & easy for operation.

● With automatic gel loading system

● Equipped with PRP gel heating system

● Gel filling volume: 0.8-5g/pc, volume can be adjusted on HMI. Filling times can be set on HMI to get higher volume

● Max. Speed: 4000 r/min

● With touch screen, for easier operation

● Equipped with ac frequency motor, with high precision speed control, calculate the RCF value automatically

● With unique vibration damper, with best shock-absorbing

● With electronic lock, for better safety

● Tolerance: ±4%

● SMC servo control, for stable running

● Detection for reagent storage tank, automatic alarming once lack of reagent

● Tolerance: ±3% (exclude tolerance of the tube itself)

Leave a message

20 Years Experience. Overall Solution Supplier.

230 Clients' Common Choice.

Being the leading company for blood collection tube production line.

Main products: Blood collection tube machine, micro/capillary blood collection tube making machine, DNA collection tube assembly line, PRP tube manufacturing machine, plastic injection molding machine, arterial blood collection syringe production line, blood culture bottle assembly machine.

Contact: Lee

Tel: 0086 13036794046

Address: Building E11, Jinrong Industrial Zone, Wangcheng District, Changsha, China